Moog Music Factory Tour

Behind the scenes where the famed analog synths are designed, engineered, built and tested

In the hubbub between panels showcasing the future of music composition and performance (like autonomous robots in operas) and outdoor shows by the likes of Giorgio Moroder, we took a breather during Moogfest (the recently revived five-day showcase of music and technology) to take a private tour of the Moog Music Factory.

Though Bob Moog (rhymes with “rogue”) was born and raised in New York City, the engineer and inventor moved to the mountain town of Asheville in 1978, where he tended to his organic garden, dreamt up new ideas for synthesizers and even taught at UNC Asheville. Now, Moogfest takes place in Asheville, North Carolina and celebrates the legacy of the man who turned electricity into music, starting with theremins to voltage-controlled analog synthesizers that have been used by everyone from The Beatles to prog rock bands and experimental artists. A few years ago, Moog Music moved its headquarters closer to downtown Asheville and the River Arts District to be more involved with the community. Four vacant buildings were renovated into an all-in-one space that serves not only as a factory, but offices and retail space as well.

Just one door separates the retail space from the production floor. “This is where we build all of the Moog products—this is our only facility in the entire world, we don’t have any other warehouses or offices. Everything we do is in this building,” says our guide Jim DeBardi, who started out as a production intern and is now part of the marketing team (one of 58 employees at Moog). The majority of the materials are sourced within the US (all of the wood comes from Knoxville, Tennessee and all of the metals come from St Louis, Missouri), although with electronics, some specific analog components have to be pulled in from overseas. For example, a timing chip that drives the oscillator in one of the synths can’t be found anywhere the States, but one of their closest circuit board manufacturers is actually in Asheville—just five minutes away—by a company called Appalachian Technology that makes the analog circuit boards in the Minimoog Voyager. It’s a stark contrast to the majority of Moog’s competitors, who mass-produce their synths in China.

“Every person that does work on any instrument in the factory does a quality check of everything that they’ve done and everything that’s been done before them. So a Minimoog will go through six people before it leaves our factory and it’ll get checked six different times,” says DeBardi. “The initial construction—putting all the parts together—takes about four hours. Then it goes through 48 hours of burn-in, which doesn’t involve physical labor but we plug the instrument in and leave it on for 48 hours. That’s because each one of these pieces is an individual piece that could fail. If a resistor’s going to pop or if an LED light’s going to burn out, it’ll happen within the first 48 hours of use. And that way, any problem that might manifest themselves, they’ll happen right here in the factory as opposed to being two weeks into someone’s home.”

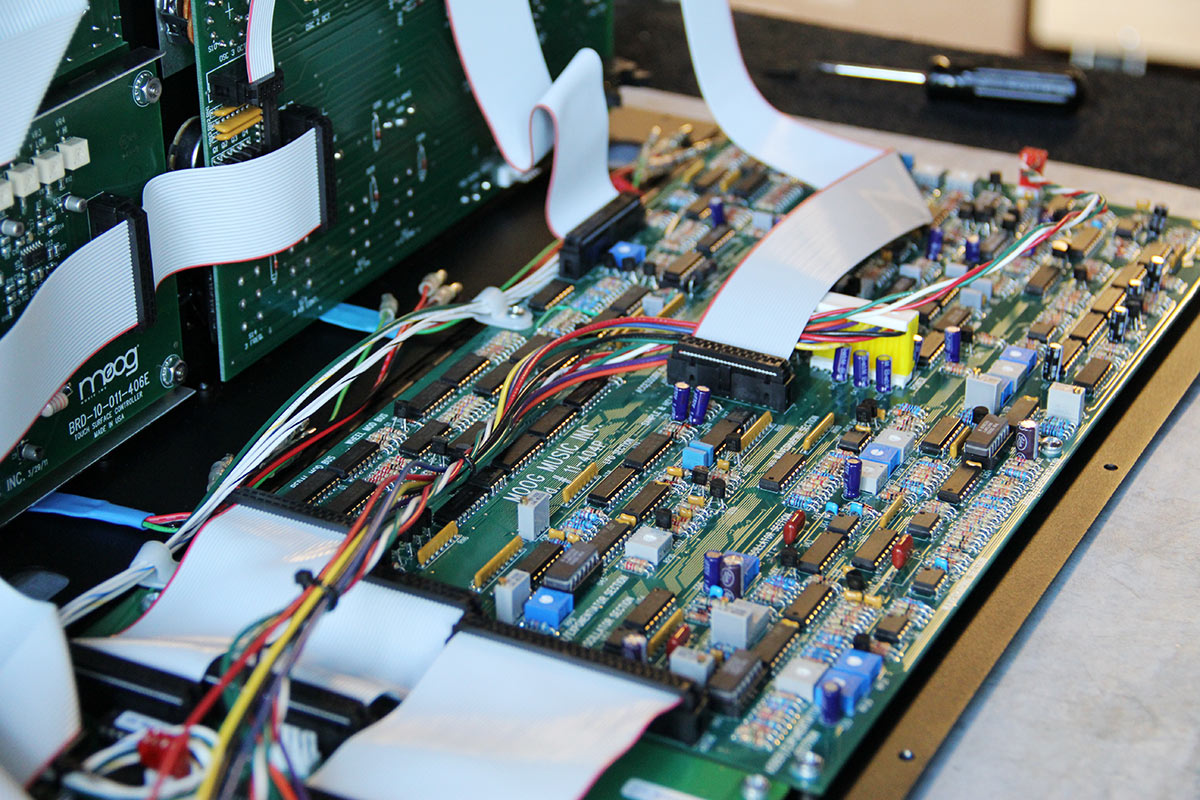

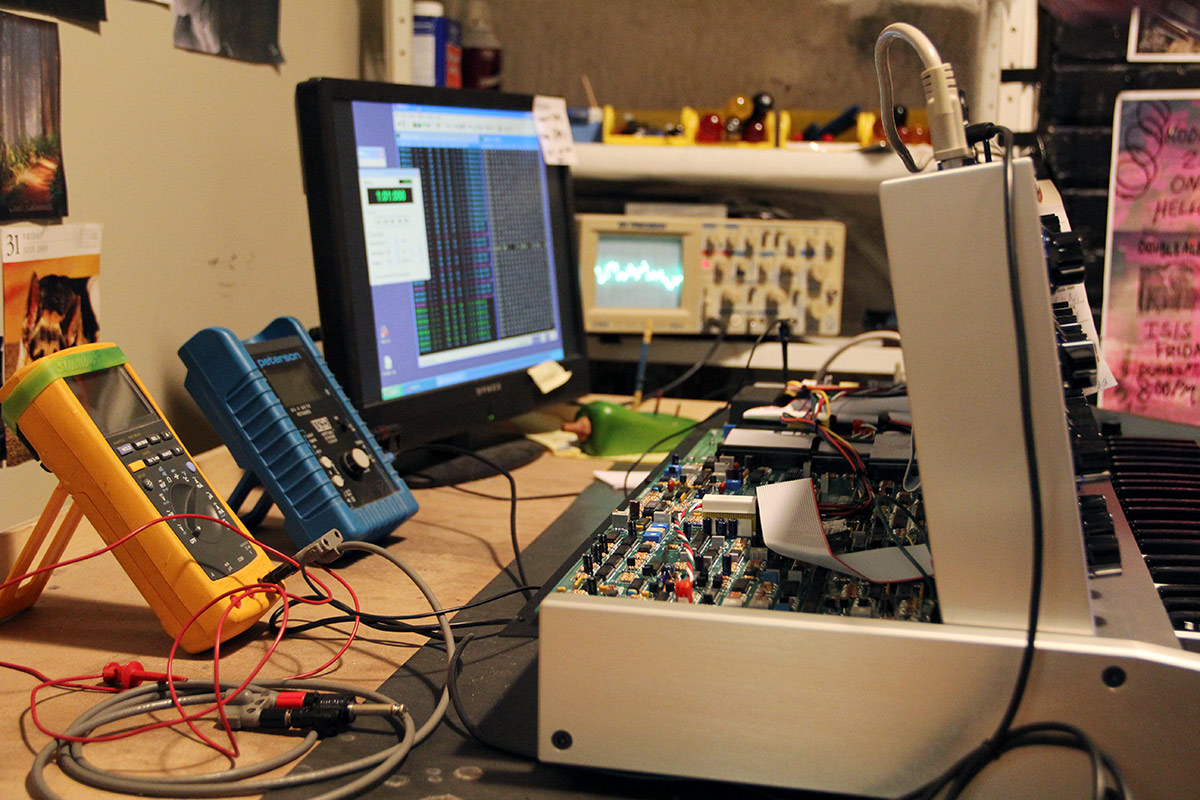

The next step after the burn-in process is calibration. DeBardi introduced us to Steven, who calibrates only Minimoogs in a dedicated room (there are two other calibration technicians who oversee their own primary products in other rooms; the smaller instruments get calibrated on the line since the process is much quicker). He will bring a synth into the room, open up the back panel to expose the circuit board, and hook up his measuring devices to it. Keeping an eye on the numerical readout of voltage and the visual representation on the oscilloscope, he basically “tunes up” the instrument; there are 30 calibration points on the Minimoog that have to be set accurately down to the millivolt.

Hand-building the instruments is an inherently slower process, but one way that Moog is able to keep up with their competitors in terms of efficiency is having their entire team under one roof. “We do all of the production here. Our designers and engineers are upstairs, we have an in-house sales and marketing team—and so anytime we need anything, we don’t have to go too far outside of the building.” If they’re building a prototype on the production floor and run into some trouble, a technician can just walk up one flight of stairs with the piece in hand and ask a question to the engineer that designed it.

All of the service is also done in-house. We poked inside the dedicated service room—the only authorized service center in the US for Moog warranty repairs. Within the chaos of labeled boxes that held four-pin IDC connectors, audio/CV jacks and more were signed posters by DJ Lance Rock (of Nickelodeon’s hit show Yo Gabba Gabba!) and Bernie Worrell (of Parliament Funk and Talking Heads). We also spied a cart carrying two synthesizers knighted in black Sharpie marker as “Humphrey Bocart.”

We’re building musical instruments and people have a very personal relationship with a device like this. You’re constantly touching it, interacting with it. It’s a tool that artists use to realize an idea they have inside and make it real.

“Even though we’re building electronics, we realize that we’re not building toasters or televisions or products that people have a passive relationship with,” says DeBardi. “We’re building musical instruments and people have a very personal relationship with a device like this. You’re constantly touching it, interacting with it. It’s a tool that artists use to realize an idea they have inside and make it real.” Therefore, Moog institutes a final check on every single instrument—not just a few that get spot checked randomly—where a trained technician (who knows how every knob should feel, how every key should react and what every waveform should sound like) goes through, top to bottom, to ensure that the playing experience is correct and uniform.

“Compared to a digital circuit, analog is a living, breathing, organic thing—the way the voltage flows through it and there’s a push and a pull, etc.,” DeBardi continues. “To build an instrument like this, to the quality standards that we have, you have to have a human touch involved in every step of the process. And really to do it the right away, you need dedicated people who know these instruments inside and out.”

This past week at Moogfest, Moog Music unveiled to the public what was thought to be their April Fool’s Joke this year: the Emerson Moog Modular System, a faithfully replicated version of Keith Emerson’s original modular system built by Moog, heard on hits like “Lucky Man” and “Hoedown.” Emerson was purportedly the first artist brave enough to take the Moog analog synthesizer, meant for staying in studios for recording sessions, on the road—which must not have been an easy feat, considering that it weighed 550 pounds. Thanks to three years of research and reverse engineering, the new system is available to those who dare to inquire about its price.

Other new Moog products to make their debut this year are the Theremini, a theremin that for the first time has the option of pitch quantization, and the Sub37, a step up from the Sub Phatty synthesizer. For those who are trying to save up for the Holy Grail modular system, you can download the Animoog app from iTunes to have a polyphonic touchscreen synth in the palm of your hand.

Moog Music’s Factory is located at 160 Broadway St, Asheville, North Carolina. For more info on store hours and touring the factory, visit Moog Music online.

Lead image and Emerson Moog Modular system image courtesy of Jeffrey Delannoy, all others by Nara Shin