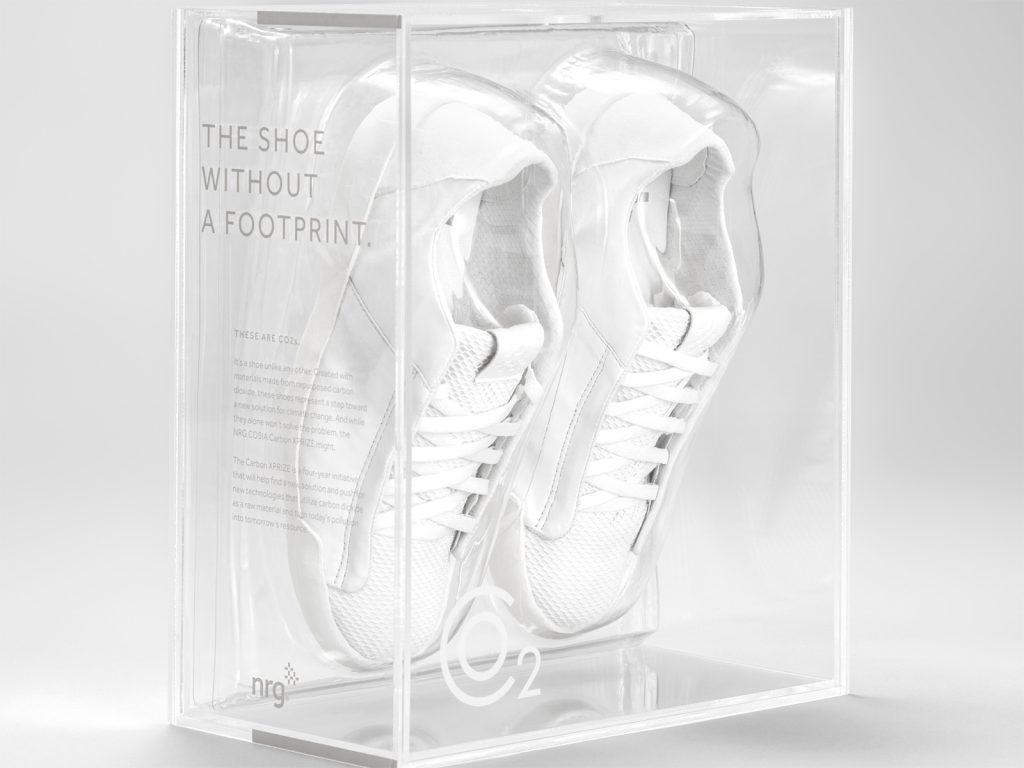

NRG’s Sneaker Composed of Repurposed CO2

A shoe without an environmental footprint by the XPRIZE-affiliate energy organization

“We recycle plastic, paper and metal; why can’t we recycle CO2?” Paul Bunje, Principal and Senior Scientist or Energy and Environment at XPRIZE, asked. With that, a $20 million competition, the NRG COSIA Carbon XPRIZE, was set into motion a year ago, inviting teams to submit business proposals on converting carbon emissions into something useful. And now, not only have we recycled CO2, but there’s a tangible prototyped product from materials composed of the repurposed greenhouse gas. It happens to be a sneaker. NRG, in the midst of the aforementioned four year partnership with Carbon XPRIZE, brought on board design engineer and inventor Marcel Botha and shoe designer D’Wayne Edwards (one of the four masterminds behind the iconic Air Jordan and founder of the Pensole Footwear Design Academy) to develop the prototype. Remarkably, NRG’s technology uses captured CO2 as the building block for the sneaker’s foam.

Much of the greenhouse gas emission hails from the energy industry, and NRG (a leader in their field) is spearheading this initiative to manage the damage and ultimately attempt to undo what has been done. For this process, they have captured CO2 that would normally be admitted into the atmosphere. They add a proprietary catalyst and in a few hours, a tactile “foam” has formed. It is this material, devoid of a carbon footprint, that has been crafted into the sneaker. Science aside, the shoe also looks good. Debuting today during New York Fashion Week at NRG’s Thought Leadership Panel is an effort to drive awareness of this material to the fashion industry and all those paying attention.

As for why the debut product happens to be a shoe, Edwards makes clear that when consumers can try on a product—and actually feel it—the idea of conservation and recycling sinks in more. And, of course, this is just one step along the way. Through the NRG XPRIZE platform, developments are hoping to be made in turning CO2 into everything from chemicals used in consumer goods, to building materials like concrete and cement, and a variety of products as far as the imagination can stretch. Semi-finalists for round two of the challenge will be announced this October—with their submissions expected roughly one year later. Round three will commence in 2019 and the program will announce the ultimate winner in March 2020. NRG will keep people updated along the way.

Images courtesy of NRG