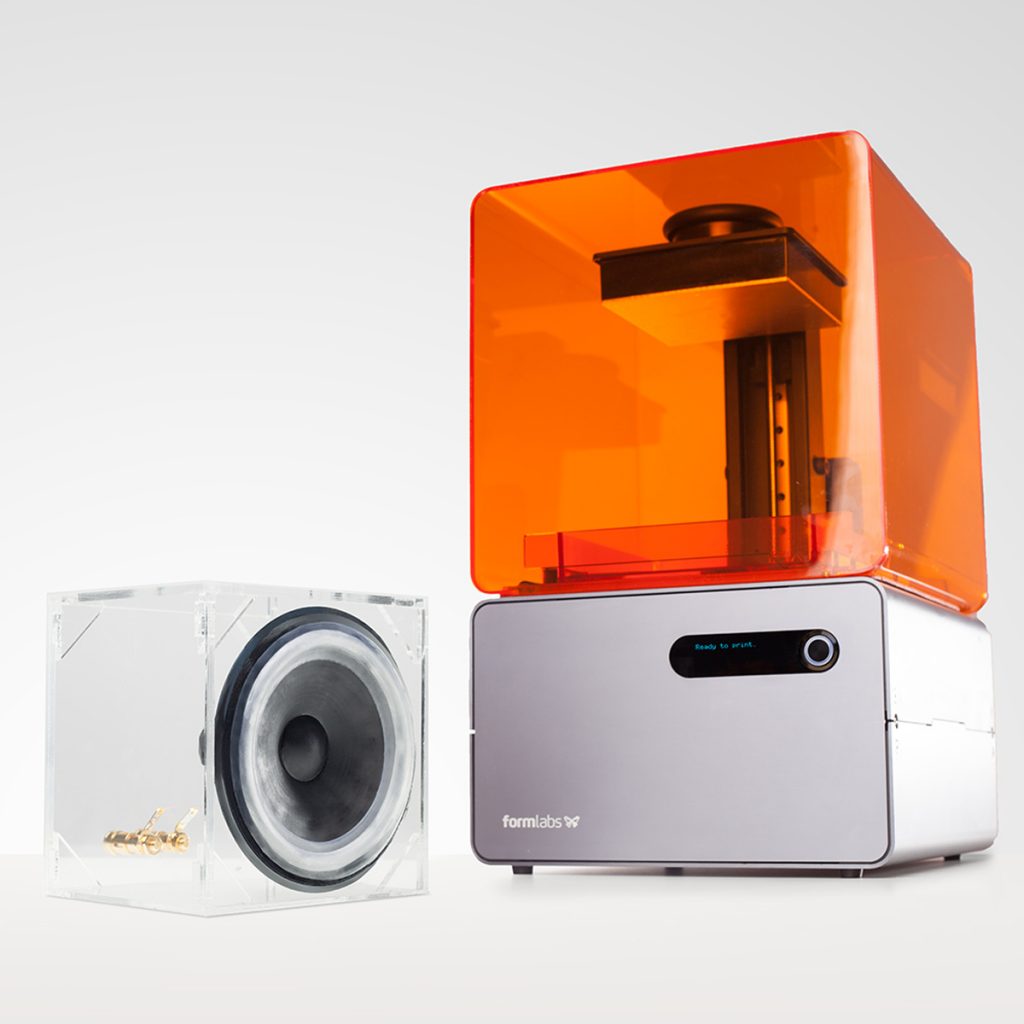

A DIY 3D-Printed Speaker From Formlabs

Updated functionality from the Form 1+ encourages further design creativity

After an almost $3 million round of Kickstarter funding in 2012 and a comprehensive, updated overhaul of their stereolithographic 3D printer two years later, Boston’s Formlabs is debuting new software features for their Form 1+ that once again keep them ahead of the curve. With efficiency as the through line, the new Draft Mode increases print resolution and Smart Supports (a print preparation function) allow for increased printing speeds while maintaining precision. This is thanks to an algorithm that minimizes contact points and material usage as the machine churns out complex objects at 200 micron layers. To demonstrate just how effective the system is, Formlabs printed a stereo speaker from scratch—everything except the wires, magnets and enclosure—and not only is the result striking, but users can also do it at home in a few steps.

As for why a speaker made the most sense to demo these updates, Formlab’s Colin Raney shares that their engineer “Adam is a passionate musician and was inspired by the new Flexible resin recently released. This was the missing link to create the flexible parts of the speaker cone that allows for the vibration in the speaker.” Every component, aside from those aforementioned, was designed within the software and printed from only two resins. Fully functional, aesthetically simple yet entirely remarkable, this do-it-yourself speaker is a true reflection of the advancements in consumer 3D printing.

The Form 1+ complete package, including the printer, resin tank, build platform, finish kit, updated free PreForm Software and one liter of the resin is available online for $3299.

Images courtesy of Formlabs