Developing Rado’s Ceramic-Metal Alloy for the DiaMaster Ceramos Collection

CEO Matthias Breschan discusses the brand’s commitment to materials for the future

Swiss watchmakers infrequently move beyond precious metals or steel for case source material. The reason is simple: consumers understand the value of platinum, various golds and stainless steel—and all of these handle daily wear in a time-tested manner. Rado, however, reinforces new material development as a primary pillar of the brand. While competitors toy with PVD or bronze, Rado has built numerous groundbreaking materials—including a proprietary, injectable ceramic-metal alloy known as Ceramos that’s employed in their DiaMaster Ceramos collection. And they continue to release new styles that highlight this invention’s beauty and versatility. Material introduction is a bold move—and one that CEO Matthias Breschan acknowledges as the brand’s future.

“Nothing gets in the way of our drive to innovate,” Breschan tells us. In fact, when the brand launched some 60 years ago, developing “le habillage” (or “the case”) was a primary focus. “Think about materials such as plasma high-tech ceramic and Ceramos. They are exciting and important, not only to Rado, but also to the watch industry as a whole,” he continues. “The idea that a watch will look just as good in years to come as it does now, will never lose its shine and is also light, scratch-resistant and comfortable to wear is extremely compelling.” Ceramos, in particular, can claim all of these attributes.

Rado also develops the technology required to manipulate these materials—something that differentiates them from competitors. “Our research and development team is really at the forefront of bringing new materials to the watch industry,” he says. “These are often materials that have proved successful in other industries and have the essential properties needed for watchmaking [which includes lightness, strength and durability].” Both the design and development teams work closely together to identify new opportunities.

With a watch material like high-tech ceramic, which Rado has used now for 50 years, the brand must sometimes explain its value in the luxury watch world. “Lightness, scratch-resistance, rapid adaptation to skin temperature and wearer comfort are inextricably linked with our watches and very unique points of differentiation with other materials,” Breschan reiterates. Further, he adds that “With Ceramos and our watches made in plasma high-tech ceramic, our main challenge is often helping consumers understand that they are actually ceramic and not precious metals or stainless steel. It’s quite an interesting challenge we face with the newest models in these materials.”

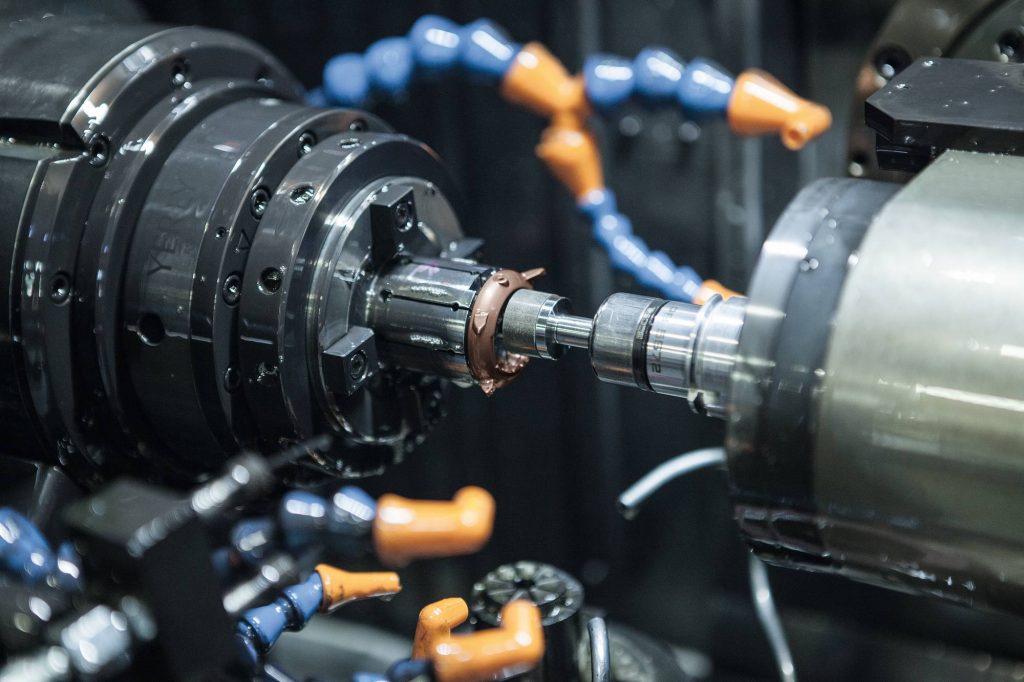

Breschan believes that Ceramos is the most exciting new material in the watch industry today, and for good reason: “90% high-tech ceramic and 10% metal alloy in an injectable form is just an incredible achievement,” he explains. “It means that we can make almost any shape and size of case. That’s really incredible. We’ve already presented models from our DiaMaster collection in Ceramos, but it’s a material you will definitely see more of in the future,” he adds.

The injectable nature of Ceramos enables Rado’s design team to experiment freely. “Design is incredibly important to Rado and we believe it goes hand in hand with our material innovation,” Breschan says. “Designers show us what the future looks like and can give us a unique perspective on the role of design in watchmaking. When our materials dictate or restrict design, that’s when we push harder to make new materials or develop new technologies for shaping or molding so we can achieve new designs. In that sense, design is absolutely essential to what we do in materials development.”

Rado’s roster of inventions is quite lengthy—with hard metal, high-tech diamond and so much more. Breschan says, “The highlights, for me, would be 1986, when we first used high-tech ceramic for the Integral bracelet links. 1998 was our very first use of plasma high-tech ceramic on the Ceramica. 2011 is perhaps the biggest breakthrough with our now signature monobloc case. That was a real revolution in watchmaking again.” They’ve created ultra-light high-tech ceramic and followed it up with the introduction of Ceramos in 2018. Simply put, Rado offers the future now, and they’re explaining the importance of each advancement as it rolls out. “I can’t predict the future,” Breschan concludes, “but I can tell you that there is much more to come.”

Images courtesy of Rado